Our Projects

Repeatability

Our long history of success has afforded us the privilege to have worked with, and for, many of the world’s largest industrial clients.

We execute on an unparalleled tradition of project leadership, adherence to exceptional standards of excellence and an acute commitment to safety in delivering an inspired customer experience.

We are able to realize significant cost savings for our customers by employing more efficient rope access and project planning methods. Some typical savings are as follows:

Inspection- 30% Cost Reduction at > 10’, Over Other Typical Methods

- 50% Cost Reduction at > 30’, Over Other Typical Methods

- 50-70% Faster Than Over Other Typical Methods

- 50-70% Cost Reduction, Over Other Typical Methods

- 50-70% Faster Than Over Other Typical Methods

- 50-70% Cost Reduction, Over Other Typical Methods

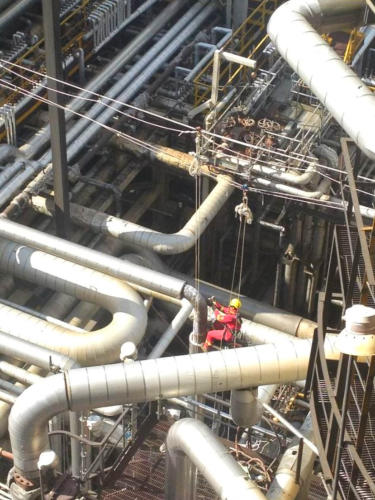

| ROOF REPLACEMENT – CANADIAN OIL SANDS |

|---|

| Recent Project Example A plan was designed using Tacten RAT Team methods to access the location, and safe out, all work being performed overhead. RAT Team specialists conducted all inspections and worked closely with the client to develop repair plans. All Repairs were completed by a composite crew. Job Summary:RAT Team was on location for 130 days. Job Scope:Safety net installation, visual, UT/pit gauge, MT Inspections, corrosion removal, sandblasting, coatings application, electrical and cable tray installation, welding and fabrication. Savings:Access cost, safety net and Installation for Tacten RAT Team took 20 days where traditional scaffold methods estimated at 45 days. The savings for our customer, on access costs alone, was in excess of $1,000,000. |

We are eager to discuss your projects and requirements. Please contact us at [email protected].